AP-6-1-INV

Current Status and Future Prospects of the SuperRail Project in France

13:45-14:15 29/11/2023

*Kévin Berger 1, Loïc Quéval 2, Hervé Caron 3, David Ferandelle 3, Arnaud Allais 4, Jean-Maxime Saugrain 4, Louise Terrien 5, Grégory Bouvier 5

1. Université de Lorraine, GREEN, F-54000 Nancy, France

2. Université Paris-Saclay, CentraleSupélec, CNRS, Laboratoire de Génie Electrique et Electrotechnique de Paris, 91190 Gif-sur-Yvette, France

3. Département de la Traction Electrique, SNCF Réseau, 93418 La Plaine Saint-Denis, France

4. Nexans, 92400 Courbevoie, France

5. Absolut System, 38170 Seyssinet-Pariset, France

Today, increasing rail traffic while ensuring continuity of service represents a major challenge for SNCF, the French rail operator. To meet this challenge, particularly in densely populated areas such as Paris, SNCF has recently launched a number of electrification projects. One aspect of these projects aims to reduce line losses in order to lower the voltage drop on the 1.5 kV rail network. Among the possible technological choices, high-temperature superconductor (HTS) cables are a promising solution.

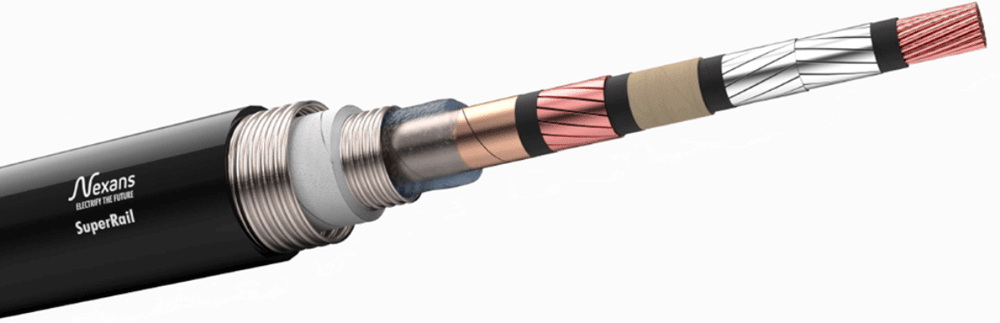

The SuperRail project, supported by the French government, will be the first installation of a HTS cable system on a commercially operated railway electric grid [1]. The project's goal is to develop, manufacture, and install an HTS DC cable system at the Montparnasse railways station in Paris. Due to the restricted space available in the city's saturated underground, the HTS technology provides the only viable solution for increasing the power supply from the railway traction substation to a group of railway tracks. This will allow for an increase in train traffic while simultaneously reducing CO2 emissions. Two 80 m long 1.5 kV-3.5 kA HTS DC cables made of 2G conductors will be installed in parallel. They are designed to meet stringent load chart requirements and to sustain a 67 kA-200 ms short-circuit current.

This paper will describe the current status of the project, as well as the selected cable and cooling system technologies. In addition, results of prospective studies on the reduction of losses in the terminations and on the advantages of using a cryo-converter, will also be discussed.

[1] https://www.nexans.com/en/newsroom/news/details/2022/06/a-world-first-in-France-at-montparnasse- train-station-nexans-installs-superconducting-cables.html

The SuperRail project is funded by the French government via the BPI as part of the France2030 program.