WB-6-3-INV

Recent Progress of Coated Conductor at Shanghai Superconductor Technology and Discussion for Fusion Application

15:00-15:30 29/11/2023

*Y. Yamada1, 2, J-M Zhu1 and B. Song1

1. Shanghai Superconductor Technology Co., Ltd, Bldg.25, 1388 Zhangdong Road, Zhangjiang Hi-Tech Park, Pudong Shanghai, P.R. China

2. Chubu University, Thin Film R&D Center, 487-8501 Aichi-ken Kasugai-shi Matsumoto-cho 1200

Recent progress of HTS magnets for compact fusion and the mass production of HTS-CC (Coated Conductor) attracted much interest in HTS industry as well as in the energy business community.

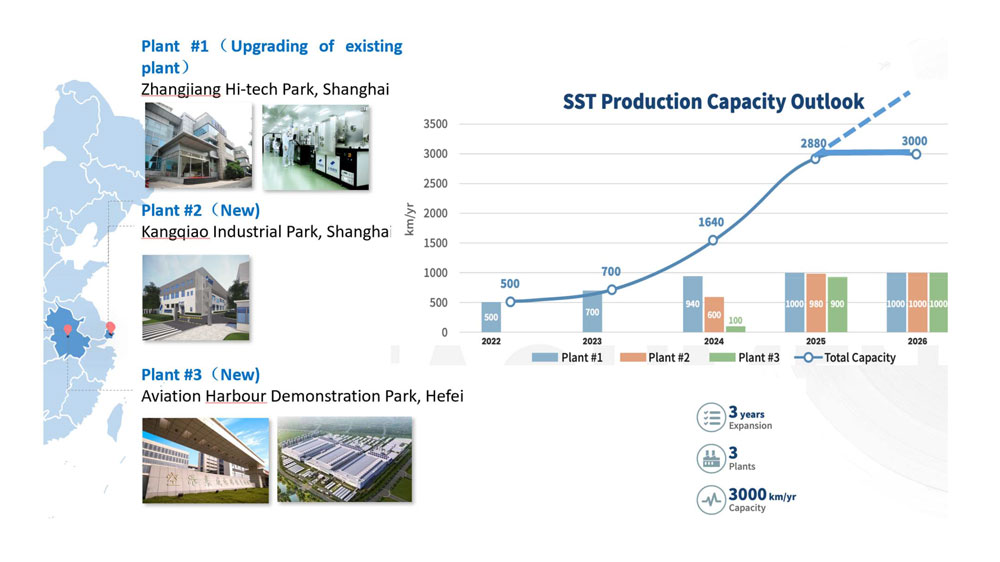

Here I first summarize the recent effort at Shanghai Superconductor Technology (SST) for the low-cost and mass production especially for fusion application as well as Ic and Jc enhancement. SST very recently has opened the new factory to aim to increase the annual production by 5 to 6 times. This could be expected to match the future large demand on fusion application or others.

In the latter half of this talk, I will introduce some discussion about the important R&D issues for fusion application. Recently I (YY) have organized “HTS conductor R&D committee for fusion application” in Japan under CSSJ (Cryogenics and Superconductivity Society of Japan) to discuss what we need in CC R&D for this application in the CSSJ community. This discussion is based on the comparison of the present REBCO CC properties and the low Tc conductor used for ITER, JT60SA or DEMO in Japan. These systems were realized by considering many factors of not only Ic or Jc, but also strength, size factors, stability, AC loss, supply amount, and so on. Referring these data, discussion will be done together with the audience for the fusion applications.