WB-7-3

Fabrication of BSCCO HTS Wires by Cryogenic Drawing and Rolling under Liquid Nitrogen Temperature

09:45-10:00 30/11/2023

*Xueqian Liu, Shengnan Zhang, Jianfeng Li, Jixing Liu, Jianqing Feng, Chengshan Li, Pingxiang Zhang

Superconducting Materials Research Center, Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China

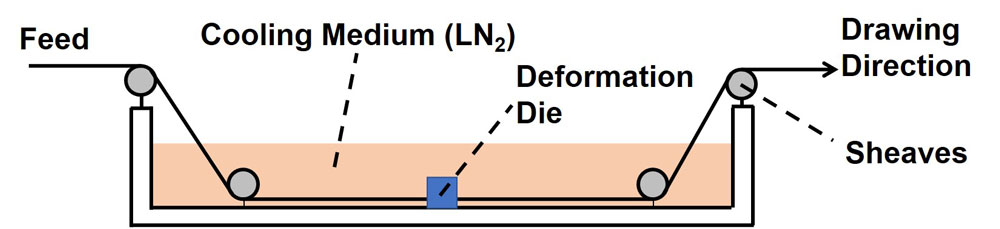

BSCCO (Bi-2212 and Bi-2223) high temperature superconductors (HTS) are expected to have great potential in terms of applications, for their high critical current capacities and stable multi-filamentary wire structures. However, during the forming process of wire, namely powder-in-tube (PIT) method, the workability of BSCCO wire is restricted by mechanical mismatch between brittle ceramic precursor powders and ductile metal sheath/matrix. Such problems would get worsen in less Ag-Superconductor ratio design for lower material cost. Moreover, to reach higher powder densification state as preferred, higher radial stress would be applied during deformation, causing the deterioration of deformation homogeneity. The problems above could be alleviated to improve the quality of final product by improving the mechanical strength of matrix/sheath. Nano-twinning induced synergistic improvement of strength and ductility under cryogenic temperature had been reported in many metals with certain stacking fault energy, including silver, the commonly used BSCCO matrix and sheath material. In this study, a novel fabrication method for the BSCCO wires was developed by introducing cryogenic temperature during the deformation process. Simultaneous improvements in both strength and plasticity of Ag and AgMg alloys were found under cryogenic temperature close to 77 K. The filament densification effect, filament deformation uniformity, and superconducting properties of BSCCO wires with different wire structures and silver-superconductor ratios were systematically evaluated and analyzed. It has been found that better densification effect with high uniformity could be achieved in single core wires by in-situ strengthening of silver sheath, which can provide and transfer extra hydrostatic pressure for powder densification during the cryogenic deformation process. Wires with cryogenic deformation showed well preserved structures without internal breakage with less intermediate annealing, indicating better plasticity of sheath metal. Higher critical current capacity with higher uniformity was also observed in cryogenic deformed specimens with nearly 20% improvement comparing with the wires fabricated under room temperature. The above results provided the feasibility of cryogenic deformation for bismuth-based wires and tapes, and the extra deformation tolerance might enable new structure designs with smaller filament size and lower Ag/SC ratios.

(1) X. Liu et al. J. Alloy. Compd. 922 (2022) 166304

(2) F. Kametani et al. Supercond. Sci. Technol. 24 (2011) 075009

(3) D. C. Larbalestier et al. Nat. Mater. 13 (2014) 375-381

(4) M. Eriksen et al. IEEE Trans. Appl. Supercond. 11 (2001) 3756-3759

(5) D. Smith et al. J. Res. Natl. Inst. Stan. 100 (1995) 119-171

(6) S. Navas et al. Cryogenics 120 (2021) 103384

(7) Q. Hu et al. Physica C 274 (1997) 204–208

(8) Y. Wang et al. Met. Mater. Int. 11 (2005) 59-62

The authors would like to acknowledge that the research is sponsored by Northwest Institute for Non-ferrous Metal Research Funding (Grant No. YK 2112)