WB-7-4-INV

Next-generation MgB2 superconducting wires: Harnessing coarse magnesium for localized internal diffusion

10:00-10:30 30/11/2023

*Jung Ho Kim1, Minoru Maeda2, Zhenan Jiang3, Nick Strickland3, Akiyoshi Matsumoto4, Yusuke Shimada5, Jun Hyuk Choi6, Seyong Choi2

1. University of Wollongong, Australia

2. Kangwon National University, Republic of Korea

3. Victoria University of Wellington, New Zealand

4. National Institute for Materials Science, Japan

5. Tohoku University, Japan

6. Sam Dong Co., Ltd, Republic of Korea

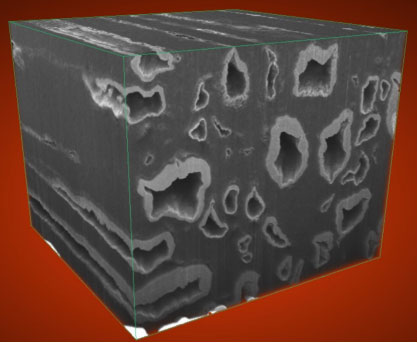

Enhancing the threshold current characteristics of MgB2 superconducting wires is crucial for practical applications. A persistent challenge arises from the formation of numerous pores during heat treatment due to magnesium evaporation. These pores significantly reduce the effective superconducting area, necessitating effective mitigation strategies. While internal diffusion processes utilizing magnesium rods have been proposed, the conventional application of such rods often results in irregular geometries of superconducting core. This study introduces an innovative approach involving coarse magnesium, which exhibits the remarkable ability to elongate within the superconducting core during the drawing process. This intriguing behaviour is akin to the presence of a bundle of small magnesium rods, giving rise to what we term the 'localized magnesium diffusion process.' Experimental results confirm a noteworthy increase in critical current density, a finding corroborated by the correlation with three-dimensional (3D) tomography.

Journal of Alloys and Compounds 954 (2023) 170148

Advanced Materials 23 (2011), 4942-4946

NPG Asia Materials 4 (2012), e3

This research was supported by National R&D Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (2022M3I9A1073924) and also supported by “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE) (2022RIS-005).