WB-7-6

Hot Uniaxial Pressing System - A new methodology for manufacturing superconducting reacted MgB2 joints for persistent mode operation

10:45-11:00 30/11/2023

Hao Lianga, Andrzej Morawskib, Dipak Patelc, Tomasz Cetnerb, Md. Motasim Billaha, Matt Rindfleischd, Richard Taylore, Yusuke Yamauchif, *Md. Shahriar A. Hossaina

a. School of Mechanical and Mining Engineering, The University of Queensland, St Lucia, Queensland 4072, Australia

b. Institute of High Pressure Physics, Polish Academy of Sciences (PAS), Sokolowska 29/37, Warsaw 01-142, Poland

c. The Commonwealth Scientific and Industrial Research Organisation (CSIRO), Lindfield, New South Wales 2070, Australia.

d. Hyper Tech Research, Inc., 539 Industrial Mile Rd, Columbus, Ohio 43228, USA

e. Applied Superconductivity Laboratory, Queensland University of Technology, Brisbane, Queensland 4001, Australia

f. Australian Institute for Bioengineering and Nanotechnology (AIBN), The University of Queensland, St Lucia, Queensland 4072, Australia

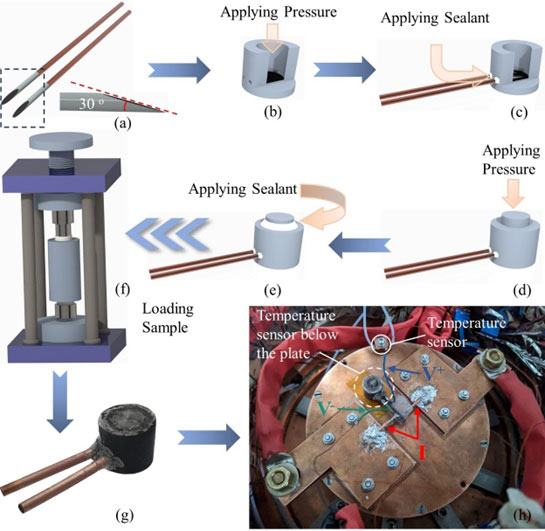

Successful superconducting joints of reacted magnesium diboride (MgB2) monofilament wires are reported in this work. The absence of a reliable method to develop superconducting joints between reacted MgB2 wires presents a major obstacle to the wider adoption of MgB2 as a material for magnet winding. A hot uniaxial pressing (HUP) system was exploited for sintering purposes since it can facilitate the formation of condensed in situ bulk on the wire filament. The wires were manufactured with an extra thick barrier material to protect the filament from damage during HUP sintering. The sintering temperature and pressure of the HUP system were varied to comprehend the best-performing joint. The terminal joining structure was utilised for the HUP system. The intergranular connectivity could be improved by depreciating the pores within the intermediate bulk of the joint. The fabricated joints retained a reasonable amount of the critical current (Ic) of the unjoined wires at different temperatures in self-field whereas the best joint retained 70.04% at 20 K in self-field. The joints were cut to study their morphology. The results showed a strong connection between the joined wires and the bulk which is believed to be the main reason for the high percentage retention of the Ic. However, due to sintering in pressurised conditions, the reaction of the in situ intermediate bulk was not completed. The X-ray diffraction result detected a significant unreacted magnesium phase in the intermediate bulk. This work obtained high-performance joints of reacted MgB2 wires which can be considered for industrial MgB2 magnetic resonance imaging magnets fabrication.

Patel D, Matsumoto A, Kumakura H, Maeda M, Kim S-H, Liang H, Yamauchi Y, Choi S, Kim J H and Hossain M S A 2021 Superconducting joints using multifilament MgB2wires for MRI application Scr. Mater. 204 114156

We are thankful for the support from the Australian Research Council (ARC) Linkage Project (LP200200689).