WB-8-2-INV

Transient Liquid Assisted Growth (TLAG), a method for increasing coated conductors throughput and meeting future

13:00-13:30 30/11/2023

*T. Puig1, R. Vlad1, L. Saltarelli1, D. Garcia1,2, K. Gupta1, C. Torres1, A. Kethamkuzhi1, E. Pach1,5, C.Pop1, D. Sanchez3, S. Rasi1, J. Banchewski1, A. Queralto1, S. Ricart1, R. Yanez2, J. Farjas3, J. Gutierrez1, C. Mocuta4, E. Solano5, X. Obradors1

1. Institut de Ciència de Materials de Barcelona, ICMAB-CSIC, Campus UAB; 08193 Bellaterra, Spain

2. Departament de Química, Universitat Autonoma de Barcelona, Campus UAB, 08193 Bellaterra, Spain

3. GRMT, Department of Physics, University of Girona, E17071-Girona, Spain

4. Diffabs beamline, Soleil Synchrotron, Paris, France

5. NCD-Sweet beamline, ALBA Synchrotron, 08290 Bellaterra, Spain nchrotron, 08290 Bellaterra, Spain

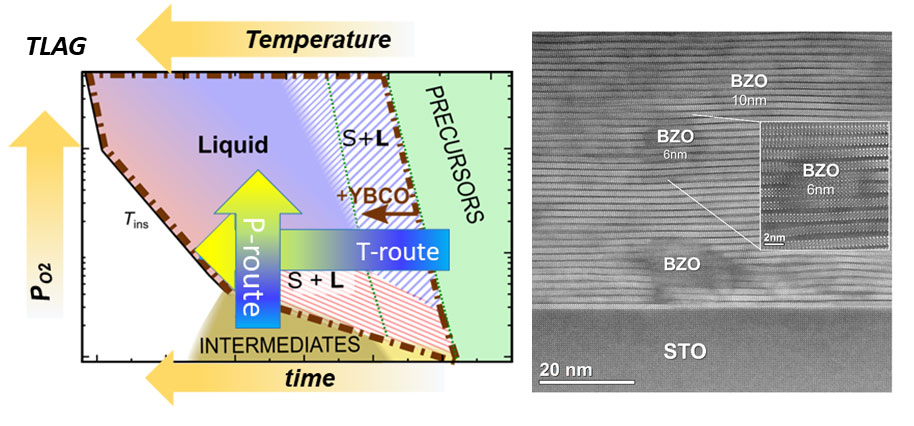

REBa2Cu3O7 coated conductors (REBCO CCs) are unique advanced materials capable of being integrated in different emerging applications such as fault current limiters, compact fusion, electric aviation or high-field NMR, among others. However, the community is facing a global need to reduce the cost/performance ratio of REBCO CC manufacturing processes, especially when CCs are to enter the market with a large number of devices. We are developing a scalable high-throughput growth approach, called "Transient Liquid Assisted Growth (TLAG)" [1,2], which uses multifunctional colloidal inks for chemical solution deposition (CSD) [3] and features ultra-high growth rates of over 1000 nm/s with high critical current densities of 3 MA/cm2 at 77 K [4]. TLAG is a high non-equilibrium liquid-solid growth process where nucleation and growth are kinetically controlled, so rapid in situ techniques were required to understand the growth mechanism and determine the correlation of the kinetic process parameters with epitaxy and growth rate [5]. Additionally, high throughput experimentation employing ink jet printed combinatorial compositional gradients are being used for fast screening of parameters. In this presentation, I will discuss the current understanding of the TLAG process, relevant process parameters for growth of CC nanocomposites, advances in growth rates and the TLAG vortex pinning capabilities. The use of fast acquisition in situ XRD imaging (<100 ms/frame) under synchrotron radiation, transmission electron microscopy, in situ resistivity experiments, and angular transport measurements have been crucial for this study.

[1] L. Soler et al, Nature Communications (2020)

[2] S. Rasi et al, J. Phys Chem C (2020)

[3] L. Saltarelli et al, ACS Appl Materials and Interfaces (2022)

[4] S. Rasi et al, Advance Science (2022)

[5] T. Puig et al, Nat Phys Rev (2023)

We acknowledge funding from EU-ERC_AdG-2014-669504 ULTRASUPERTAPE, EU-ERC-PoC-2020-IMPACT, EU-ERC-PoC-2022-SMS-INKS, CSIC-TRANSENER-PTI+, MICIN-SUPERENERTECH