WB-8-5

The proposal of a new class of coated conductors using Ca-substituted YBCO on the moderately oriented substrates

14:00-14:15 30/11/2023

*Kentaro Yamamoto, Tomoya Horide, Yutaka Yoshida

Institution Nagoya University, Japan

Introduction

For superconductor application, high critical current density (Jc) is required. YBa2Cu3Oy(YBCO) is a promising high-Tc superconductor because it currently has the highest Jc in a magnetic field. Grain boundaries of YBCO exhibit a weak link for the superconducting current due to the short coherence length of a few Å and pair symmetry [1]. Therefore, the Jc degradation due to the weak link problem should be suppressed for power and energy applications.

JcGB) depends on the grain boundary tilt angle and decreases exponentially with the tilt angle, high Jc can be obtained by texturing the YBCO films. The Ion Beam Assisted Deposition (IBAD) method is used to fabricate the textured substrates. The half width at full maximum of φ scan (Δφ), which shows the degree of in-plane orientation, is as small as 3° in the currently most optimized process. Highly oriented substrates (Δφ<5°) are used for the coated conductors. The second approach is to improve the JcGB by elemental doping such as Ca. If the JcGB can be improved by the doping, the moderately oriented substrates with Δφ=7-10° become available. It has been reported that the Ca doping improves the JcGB for the tilt angle of 7-10° in the YBCO bicrystalline films [2]. However, there are few reports on the fabrication of Ca-doped YBa2Cu3Oy(CYBCO) deposited on the IBAD tapes. Therefore, the Jc property of the CYBCO coated conductors is still unclear. In this study, we fabricate high performance CYBCO films on moderately oriented substrates to demonstrate the Jc improvement by Ca doping even in coated conductors.

Experimental method

YBCO and CYBCO films with a thickness of 200-300 nm were deposited on IBAD-MgO substrate using pulsed laser deposition (PLD) with a KrF excimer laser. Here the Ca doping content was 5%. The top layer of the IBAD substrates is a CeO2 layer with orientations Δφ = 3, 7, 9.8, and 12.3°. Δφ = 3, 7, 9.8 and 12.3°correspond to highly oriented IBAD(H-IBAD), moderately oriented IBAD(M-IBAD), and weakly oriented IBAD(W-IBAD), respectively. The H-IBAD is used for the coated conductors, and the orientation of the M-IBAD and W-IBAD is insufficient for a substrate for coated conductors. The deposition temperature and oxygen partial pressure during deposition were 830-900°C and 53 Pa, respectively. The crystallographic orientation of the films was evaluated by X-ray diffraction analysis. A bridge with a width of 100 µm and a length of 1 mm was fabricated by laser etching for Jc measurement. The Jc-B characteristics of the film were measured using Physical Properties Measurement System(PPMS) in the magnetic field of 0-9 T and temperatures of 20-77 K.

Experimental results and discussion

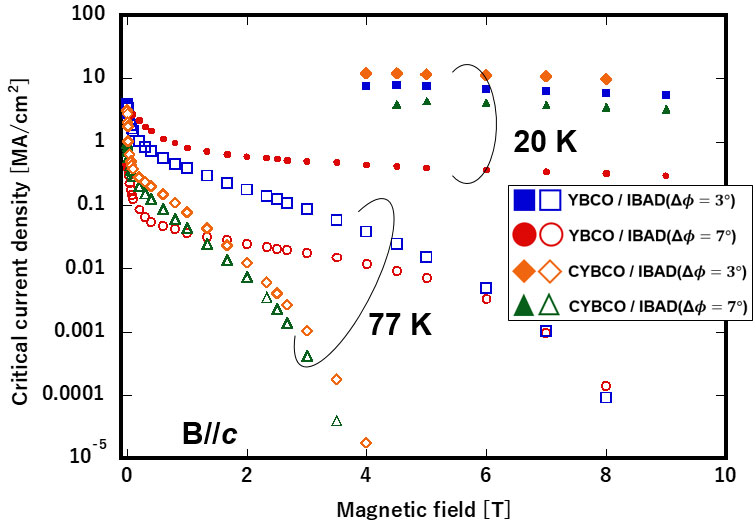

Figure 1 shows the Jc - B characteristics of YBCO and CYBCO films deposited on the IBAD (Δφ = 3°) and IBAD (Δφ = 7°) at 20 K and 77 K in a magnetic field aligned with the c-axis. The Jc decreases with Δφ, which is consistent with the result in the bicrystalline films. The Jc of CYBCO/IBAD (Δφ = 7°) (0.94 MA/cm2) is about twice as high as that of YBCO/IBAD (Δφ = 7°) (0.44 MA/cm2) at 77 K and 0 T. However, the CYBCO/IBAD (Δφ = 7°) film does not have high Jc in magnetic field at 77 K due to the low Tc (83-84 K). However, a tenfold improvement in Jc was observed at 20 K and 9 T from 0.28 MA/cm2 (YBCO/IBAD (Δφ = 7°)) to 3.2 MA/cm2 (CYBCO/IBAD (Δφ = 7°)). The JcGB is significantly reduced by the grain boundary with a tilt angle higher than 4.5° [3]. The Jc in the low-field region was decreased in the YBCO/IBAD (Δφ = 7°), while the Jc degradation in the low-field region was suppressed in the CYBCO/IBAD (Δφ = 7°). This suggests that Ca doping improves the JcGB for the tilt angle of ~7° in the coated conductor. Furthermore, the in-field Jc in the YBCO/IBAD (Δφ = 7°) is much lower than that in the YBCO/IBAD(Δφ = 3°) at 20 K. However, the Jc-B properties of the CYBCO/IBAD (Δφ = 7°) are comparable to those of YBCO/IBAD(Δφ = 3°) at 20 K. Although the YBCO/H-IBAD is the conventional coated conductor, this study suggests that the CYBCO/M-IBAD is a new class of coated conductors whose substrate selection and process design are expanded.

[1] P. Chaudhari, R. H. Koch, R. B. Laibowitz, T. R. McGuire, and R. J. Gambino, Phys. Rev. Lett. 58, 2684 (1987).

[2] Sang-li Kim, David C. Larbalestier, Journal of Applied Physics 128, 103905 (2020).

[3] D. T. Verebelyi, et al. Appl. Phys. Lett. 76, 1755-1757 (2000).

Fabrication of IBAD-MgO substrates was supported by Dr. A, Ibi, and Dr. T. Izumi at AIST. This work was partly supported by JSPS-KAKENHI(20H02682, 21H01872), NEDO, The Kazuchika Okura Memorial Foundation, and The Hibi Science Foundation.