WB-9-1-INV

Current and mechanical characterization of Distributed Tin method Nb3Sn wire

14:30-15:00 30/11/2023

*KAWASHIMA Shinya 1, KATO Hiroyuki 2, MURAKAMI Yukinobu 2, SAITO Kazuyoshi 2, Mio NAKAMOTO 3, SUGANO Michinaka 4, OGITSU Toru 4, OGURO Hidetoshi 5, AWAJI Satoshi 6, Simon HOPKINS 7 and Amalia BALLARINO 7

1. Kobe Steel, Ltd., Kobe, Japan

2. Japan Superconductor Technology, Inc., Kitakyushu, Japan

3. The Graduate University for Advanced Studies

4. High Energy Accelerator Research Organization , Tsukuba, Japan

5. Tokai University, Hiratsuka, Japan

6. Tohoku University, Sendai, Japan

7. the European Organization for Nuclear Research

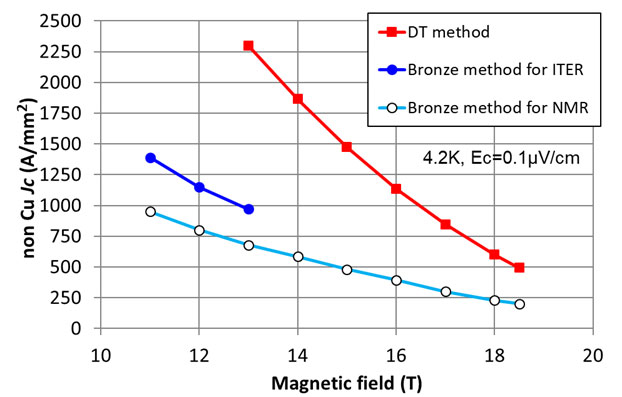

Kobe Steel Ltd. (KSL) has been doing researches of Nb3Sn wire since the 1980s. Japan Superconductor Technology, Inc. (JASTEC), which belongs to Kobe Steel Group, has been manufacturing superconducting wires and magnets. In respect of the superconducting wires, JASTEC has high production capacity in bronze-processed Nb3Sn wires and is one of the main supplier of Nb3Sn strands used for ITER project. To increase Jc, we made the filament diameter finer and improve the heat treatment and achieved very high performance of non-Cu Jc = 800~1200 A / mm2 at 12 T, 4.2 K by the bronze method.

Another feature of the bronze method is that there are few voids in the matrix after the Nb-Sn diffusion reaction. When the Cu ratio is 0.3, the 0.2% proof stress is approximately 190 MPa, and it can be said that this wire has a good balance between Jc and strength.

Currently, according to the assumed specification of the Nb3Sn for the accelerator magnets of the FCC (Future Circular Collider) planned by CERN (European Organization for Nuclear Research), it is required to achieve extremely high Jc. The target Jc is set to 1,500 A/mm2 at 16 T, 4.2 K. We have developed high performance Nb3Sn wire via DT (Distributed Tin) method, which is a type of internal Sn method with single barrier. So far, non-Cu Jc of 1,100 A/mm2 at 16 T, 4.2 K has been achieved by reducing Sn diffusion length and optimizing Ti content of the DT method.

In addition, multi Nb3Sn wires are cabled for FCC, but at this time, compressive deformation is added to the Nb3Sn wires, and there is concern about deterioration of Jc characteristics. Compared to the bronze method, the DT method has a large amount of Nb3Sn and Kirkendall voids, which causes deterioration of mechanical properties. When the Cu ratio is 0.3, the 0.2% proof stress is approximately 130 MPa.

Therefore, we need to develop Nb3Sn that not only has a high Jc but also has excellent mechanical properties and robustness. In addition to the Jc characteristics, we will also report the mechanical characteristics of DT method on the day.

This work was supported by the CERN and KEK under contract. Appendix 19 to the Agreement on Collaborative Work between CERN and KEK (ICA-JP-0103)