WB-9-2

The Stoichiometry and Defects of Nb3Sn superconductors

15:00-15:15 30/11/2023

*Mahboobeh Shahbazi1,2, Ali Dehghan3, Jose Alarco1,2, Ian Mackinnon2,4

1. Centre for Materials Science and School of Chemistry and Physics, Queensland University of Technology (QUT), QLD, 4001, Brisbane, Australia

2. Centre for Clean Energy Technologies and Practices, QUT, QLD, 4001, Brisbane, Australia

3. The University of Queensland, School of Mechanical and Mining Engineering, The University of Queensland, Brisbane QLD 4072, Australia

4. School of Earth and Atmospheric Sciences, QUT, QLD, 4001, Brisbane, Australia

While Nb3Sn was discovered half a century ago, it continues to hold a crucial role in applications involving high-field magnets. These applications include nuclear magnetic resonance spectroscopy [1], Future Circular Colliders [2], and the International Thermonuclear Experimental Reactor (ITER) [3]. Nb3Sn is an intermetallic compound of niobium and tin with an A15-type crystal structure. This compound is extensively used in industrial settings as a type II superconductor. Nb3Sn can be manufactured by the Bronze route [4, 5], internal tin process [6, 7], powder in tube [8], and modified jelly roll process [9]. Pure annealed Nb3Sn superconductors exhibit limited current-carrying capabilities due to the formation of a Lorentz force on flux lines when current passes through the material, leading to energy dissipation and eventual loss of superconductivity. To address this issue, "flux-pinning" mechanisms can be employed by introducing defects in the superconductor to immobilize flux lines.

In this study, we focused on Nb3Sn superconductors and investigated how grain boundary density and stoichiometry can enhance the critical current density (Jc). Previous research on Nb–Ti showed that an increase in α-Ti precipitate volume percentage leads to a linear increase in Jc [10]. Hence, the introduction of pinning defects and grain size refinement are essential factors in developing efficient technical superconductors. To optimize the transport properties of Nb3Sn, it is crucial to identify the influence of composition, grain size, and strain state on superconducting properties.

Our experimental approach involved systematically evaluating the impact of synthesis methods, annealing temperature and time on microstructure and superconducting properties of Nb3Sn. Nb3Sn superconducting bulks were fabricated using arc melting with subsequent heat treatments to analyze the change in microstructure and superconducting behaviour. Techniques such as X-ray diffraction, scanning electron microscopy, Transmission electron microscopy, electron probe microanalysis, energy dispersive X-ray spectroscopy, and physical property measurements were employed for comprehensive characterization of microstructure and physical properties.

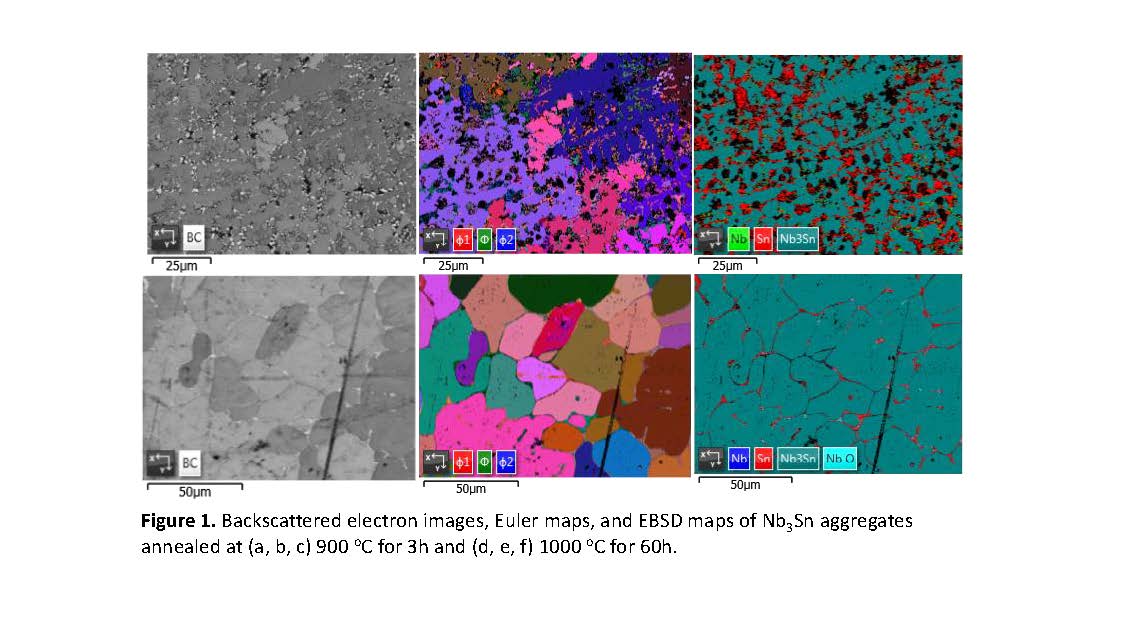

Magnetization measurements of Nb3Sn bulks have shown that the Jc, of an arc-melted Nb3Sn sample annealed at 1000°C for 60 hours can significantly enhance performance compared to arc melted Nb3Sn without annealing or to arc-melted Nb3Sn annealed at a lower temperature of 900 oC for 3h. The EBSD and TEM analysis confirms precipitation of Sn in grain boundaries for Nb3Sn bulk annealed at 1000 oC for 60h. The enhancement of Jc can be attributed to the precipitation of Sn at grain boundaries (Figure 1), which induces effective pinning centers; thus, boosting the current density. Magnetization measurements of the annealed Nb3Sn sample reveal an impressive critical current density of Jc=8.3×104 A/cm2 at 10 K compared with 2.3×104 A/cm2 for arc melted Nb3Sn with a shorter annealing time (3h) at 900 oC (Figure 2). In addition, flux jumping was observed at 5K for Nb3Sn bulk annealed at 1000 oC for 60h.

In conclusion, this study sheds light on the importance of optimizing the microstructure and superconducting properties of Nb3Sn superconductors through appropriate synthesis methods and annealing procedures. The findings highlight the potential for achieving very high critical current densities, making Nb3Sn an excellent candidate for various high-field magnet applications. These advancements pave the way for more efficient and powerful superconducting technologies in scientific research and industrial applications.

[1] T. Miyazaki, N. Matsukura, T. Miyatake, M. Shimada, K. Takabatake, K. Itoh, T. Kiyoshi, A. Sato, K. Inoue, H. Wada, Development of Bronze-Processed Nb3Sn Superconductors for 1GHz NMR Magnets, in: U.B. Balachandran, D.G. Gubser, K.T. Hartwig, R.P. Reed, W.H. Warnes, V.A. Bardos (Eds.), Advances in Cryogenic Engineering Materials, Springer US, Boston, MA, 1998, pp. 935-941.

[2] D. Tommasini, Nb3Sn Accelerator Dipole Magnet Needs for a Future Circular Collider, in: D. Schoerling, A.V. Zlobin (Eds.), Nb3Sn Accelerator Magnets: Designs, Technologies and Performance, Springer International Publishing, Cham, 2019, pp. 427-439.

[3] N. Mitchell, M. Breschi, V. Tronza, The use of Nb3Sn in fusion: lessons learned from the ITER production including options for management of performance degradation, Superconductor Science and Technology 33 (2020) 054007.

[4] V. Abächerli, D. Uglietti, B. Seeber, R. Flükiger, (Nb,Ta,Ti)3Sn multifilamentary wires using Osprey bronze with high tin content and NbTa/NbTi composite filaments, Physica C: Superconductivity 372-376 (2002) 1325-1328.

[5] J. Cheng, Q. Wang, H. Wang, Y. Dai, Microstructure evolution of Nb3Sn superconductors during diffusion treatment by bronze route, Rare Metals 31 (2012) 446-450.

[6] X. Wu, X. Peng, M.D. Sumption, M. Tomsic, E. Gregory, E.W. Collings, Ti and Sn diffusion and its influence on phase formation in internal-tin Nb3Sn superconductor strands, IEEE Transactions on Applied Superconductivity 15 (2005) 3399-3402.

[7] M.B. Field, Y. Zhang, H. Miao, M. Gerace, J.A. Parrell, Optimizing Nb3S Conductors for High Field Applications, IEEE Transactions on Applied Superconductivity 24 (2014) 1-5.

[8] X.F. Lu, D.P. Hampshire, The field, temperature and strain dependence of the critical current density of a powder-in-tube Nb3Sn superconducting strand, Superconductor Science and Technology 23 (2010) 025002.

[9] D.P. Hampshire, H. Jones, The Detailed Investigation of the Critical Current Density of Optimized Nb3Sn Modified Jelly Roll Wire throughout Its Entire Superconducting Phase Including a Comparative Study with a Similar Non-Optimized Composite, physica status solidi (b) 141 (1987) 229-237.

[10] A.W. West, D.C. Larbalestier, Alpha-Titanium Precipitation in Niobium-Titanium Alloys, in: R.P. Reed, A.F. Clark (Eds.), Advances in Cryogenic Engineering Materials, Springer US, Boston, MA, 1982, pp. 337-344.

The authors are grateful to the Central Analytical Research Facility at Queensland University of Technology for access to characterisation facilities. MS is grateful to the Queensland Government for an Advance Queensland Research Fellowship and ARENA Contract no. 2018/RND012 which partially supported this work.